Mandatory Procedures in AS 9100 Documentation

Source: Dev.to

AS 9100 is a globally recognized quality‑management standard specifically developed for the aerospace industry. It focuses on ensuring safety, reliability, and consistency in products and services. One of the core elements of AS 9100 is documented procedures, which provide a structured way for organizations to define how key activities are carried out. Mandatory procedures form the backbone of AS 9100 documentation, helping organizations operate in a controlled and predictable manner while meeting customer and regulatory expectations.

Role of Procedures in an Aerospace Quality Management System

In the aerospace sector, even small errors can lead to serious consequences. Procedures play a vital role in preventing such issues by defining clear steps, responsibilities, and controls. They ensure that work is carried out the same way every time, regardless of who performs it. This consistency supports:

- Product safety

- Operational efficiency

- Traceability

Well‑documented procedures also help employees understand their roles and how their tasks contribute to overall quality objectives.

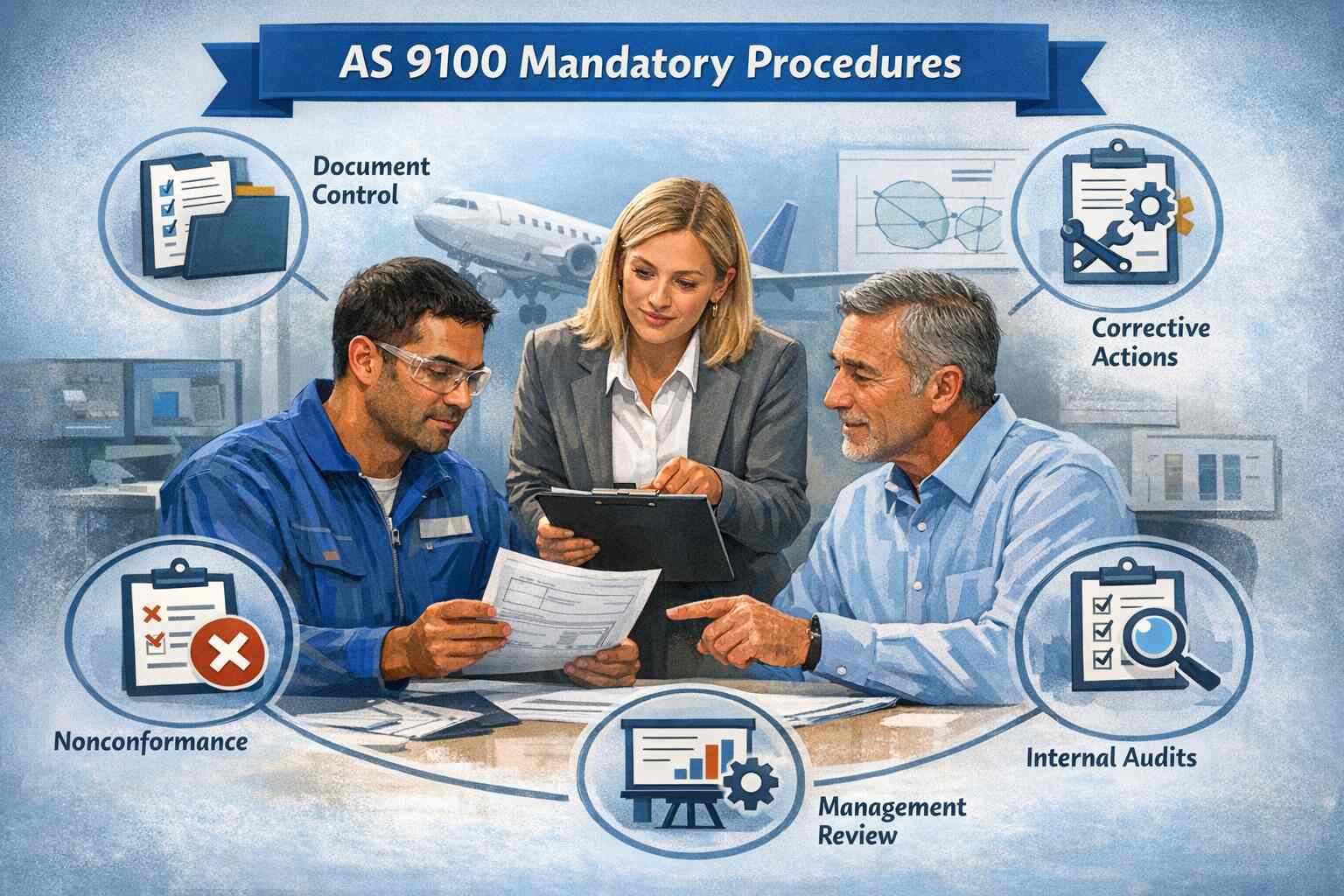

Key Mandatory Procedures Required by AS 9100

In AS 9100 documentation, the mandatory procedures establish a structured framework for controlling and improving the aerospace quality‑management system. They typically cover:

- Control of documented information

- Management of records

- Control of nonconforming outputs

- Corrective actions

- Internal audits

- Management review

Together, these procedures ensure consistency in operations, effective handling of issues, regular evaluation of system performance, and continual improvement. By defining clear responsibilities and processes, they help organizations meet customer, regulatory, and safety requirements while maintaining audit readiness and overall system effectiveness.

Procedure for Management Review

The procedure outlines how top management formally reviews the aerospace quality‑management system to ensure its continuing suitability, adequacy, and effectiveness. It defines:

- Frequency of the review

- Responsibilities and inputs (audit results, customer feedback, process performance, risk status, corrective actions)

- Required outputs (decisions on improvements, resource needs, changes to the quality system)

The documented evidence of leadership involvement supports continual improvement, product safety, and compliance with AS 9100 requirements.

Procedure for Document and Data Control

This procedure defines how an organization creates, reviews, approves, updates, and distributes documents and data that support the aerospace quality‑management system. It ensures that:

- Only current, authorized versions are available at points of use

- Obsolete or superseded documents are properly identified and controlled to prevent unintended use

Procedure for Corrective Action

The procedure provides a structured approach for identifying, investigating, and eliminating the root causes of nonconformities to prevent recurrence. It outlines how issues arising from audits, customer feedback, process failures, or product nonconformities are recorded, analysed, and addressed through appropriate corrective actions.

Procedure for Control of Quality Records

This procedure defines how quality records are identified, collected, stored, protected, retained, and disposed of to provide objective evidence of conformity and effective operation of the aerospace quality‑management system. It ensures that records remain:

- Legible

- Readily retrievable

- Securely maintained throughout their retention period

The result is improved traceability, regulatory compliance, audit readiness, and confidence in product quality and system performance as required by AS 9100.

Other Important Procedures

In addition to the mandatory procedures listed above, aerospace organizations typically maintain procedures for:

- Internal audit

- Control of monitoring and measuring equipment

- Training

- Failure‑Mode‑Effect Analysis (FMEA)

- Supplier first‑article inspection

- Configuration management

- Risk management

- Customer‑satisfaction survey

- Purchasing

Benefits of Well‑Defined AS 9100 Procedures

Well‑defined procedures offer numerous benefits beyond compliance:

- Clarity – Clearly outline what needs to be done and by whom.

- Employee confidence – Guidance reduces uncertainty, leading to better performance and fewer mistakes.

- Audit ease – Documented procedures simplify demonstration of control and preparedness.

- Efficiency – Over time, procedures streamline work and reduce waste.

- Quality culture – Consistent use reinforces a strong, organization‑wide focus on quality.

How Mandatory Procedures Support Continual Improvement

Mandatory procedures are not just about maintaining compliance; they also enable continual improvement. By following documented processes, organizations can:

- Identify gaps, inefficiencies, and improvement opportunities.

- Capture feedback from audits, reviews, and daily operations.

- Refine procedures over time, strengthening the overall quality‑management system.

Conclusion

Mandatory procedures in AS 9100 documentation are essential for ensuring consistency, safety, and compliance in aerospace organizations. They provide clear guidance, reduce risks, and form the foundation for a robust, continually improving quality‑management system.

and support continual improvement. By maintaining well-structured and up-to-date procedures, organizations can build a reliable quality management system that meets industry expectations and supports long-term success.