A Definitive Guide to Warehouse Utilisation

Source: Dev.to

Overview

A warehouse is, fundamentally, just a 3‑D box. Utilisation is simply the measure of how much of that box you are actually using.

While logistics can feel complicated—filled with WMS data, erratic SKUs, and complex spreadsheets—everything eventually boils down to physics. If you understand the geometry of the box, the metrics will take care of themselves.

In this guide we will strip away the complexity and rebuild the concept of warehouse utilisation from the ground up, moving from the physical walls to the logic of your dashboard.

Table of Contents

- 1. The Physics: What Warehouse Dimensions Really Mean

- 2. The Reality Check: Why Gross Volume Is a Lie

- 3. The Inventory Cube: Measuring What Matters

- 4. Metric #1: Cubic Utilisation (The “Air” Check)

- 5. Metric #2: Pallet Position Utilisation (The “Slot” Check)

- 6. The Paradox: Why You Can Be Both Full and Empty

- 7. Real‑World Scenario: When Ops Says “Full” but Data Says “Empty”

- 8. The Framework: Building Your Utilisation Template

1. The Physics: What Warehouse Dimensions Really Mean

Forget your inventory spreadsheets for a moment. Imagine your warehouse is completely empty—no racks, no forklifts, no people. It has only three physical dimensions:

- Length: Front to back

- Width: Left to right

- Height: Floor to the highest safe storage level

These dimensions form a massive rectangular box. In engineering terms, this is your Gross Warehouse Volume.

The Calculation

Length: 60 m

Width: 40 m

Height: 10 m

Volume = 60 m × 40 m × 10 m = 24,000 m³⚠️ Crucial Note: This number represents the total volume of air within the walls. It does not mean you can store 24,000 m³ of inventory. Building a business plan on this figure will set you up for failure.

2. The Reality Check: Why Gross Volume Is a Lie

Warehouses are not solid blocks of cheese; they are operational environments. You lose a massive amount of that gross volume to operational necessities:

- Aisles: For forklifts to travel.

- Structure: Columns and beams.

- Staging: Inbound and outbound docks.

- Infrastructure: Offices, battery‑charging stations, fire‑clearance zones.

- Rack Structure: The steel of the racking itself.

To get a realistic number, professionals apply a Usable Space Factor—a percentage representing layout efficiency.

Typical Usable Space Factors

| Efficiency Level | Factor |

|---|---|

| Poor layout / wide aisles | 0.55 – 0.60 |

| Average warehouse | 0.65 – 0.75 |

| Highly optimised / VNA (Very Narrow Aisle) | 0.80+ |

The Adjusted Calculation

Assume an average efficiency factor of 0.75:

Usable Volume = 24,000 m³ × 0.75 = 18,000 m³📌 Takeaway: This 18,000 m³ is your actual canvas. It is the denominator for all your cubic calculations.

3. The Inventory Cube: Measuring What Matters

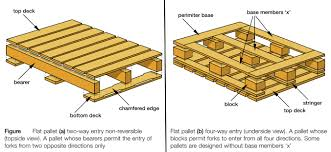

Now that we know the size of the box, we need to measure what goes inside the box. Every pallet occupies a specific volume of space, defined by its footprint and its loaded height.

Example Pallet

- Dimensions: 1.2 m (L) × 1.0 m (W) × 1.5 m (H)

- Pallet Cube: 1.2 × 1.0 × 1.5 = 1.8 m³

If your WMS tells you you are currently holding 1,000 pallets, your inventory cube is:

Inventory Cube = 1,000 pallets × 1.8 m³ = 1,800 m³4. Metric #1: Cubic Utilisation (The “Air” Check)

Cubic Utilisation tells you how much of your usable space is occupied by product and how much is just air.

The Formula

Cubic Utilisation = Inventory Cube ÷ Usable Warehouse CubeThe Result

1,800 ÷ 18,000 = 0.10 → 10%What this means: In this scenario only 10 % of your usable warehouse space is physically occupied by goods. The rest is air—empty aisles, space above pallets, or voids between loads.

Even world‑class facilities rarely exceed 25‑30 % true cubic utilisation because accessibility is essential. Nevertheless, this metric is vital for answering the question: “Are we wasting vertical space?”

5. Metric #2: Pallet Position Utilisation (The “Slot” Check)

Cubic utilisation is about volume. Pallet Position Utilisation is about slots—the metric most operations managers check daily.

A pallet position is a single physical location (a slot) that can hold one pallet.

The Calculation

If your racks have:

- 100 bays

- 5 levels high

- 1 pallet deep

Total Positions = 100 × 5 × 1 = 500 PositionsWith 425 pallets in stock:

Pallet Position Utilisation = 425 ÷ 500 = 0.85 → 85%6. The Paradox: Why You Can Be Both Full and Empty

(Content for this section was truncated in the original source. Insert the intended explanation here, preserving the original tone and examples.)

7. Real‑World Scenario: When Ops Says “Full” but Data Says “Empty”

This is the most common argument in warehousing.

- Ops Manager: “We are full! I have nowhere to put this inbound shipment.”

- Analyst: “My spreadsheet shows cubic utilisation is only 12 %. We have plenty of room.”

Who is right?

Both are correct.

- The Ops Manager is out of slots (pallet utilisation).

- The Analyst sees wasted air (cubic utilisation).

The Solution

When this gap exists, don’t rent more space—fix your profile:

- Check Beam Levels – Are short pallets occupying tall rack openings? Lower the beams to create a new level.

- Consolidate – Do you have five half‑filled pallets of the same SKU? Combine them.

- Tunnelling – Can you use the space above cross‑aisles for storage?

Rule of Thumb:

- Use Pallet Utilisation for daily operations (receiving/shipping).

- Use Cubic Utilisation for strategic planning (layout design/expansion).

8. The Framework: Building Your Utilisation Template

When you build a dashboard or Excel template, mirror the logic above. It isn’t magic; it’s a cascade of calculations.

| Section | Data Input | Calculation / Output |

|---|---|---|

| 1. Building Dimensions | Length, Width, Height | Gross Volume |

| 2. Constraints | Usable Space Factor (e.g., 0.75) | Usable Volume |

| 3. Inventory Data | Pallet Count, Pallet Dimensions | Inventory Cube |

| 4. Rack Capacity | Bays, Levels, Depth | Total Pallet Positions |

| 5. KPI Dashboard | (Calculated Fields) | Cubic Utilisation % Pallet Utilisation % |

The Most Critical Concept for a Warehouse Planner

You can have high pallet utilisation and low cubic utilisation at the same time.

How?

Imagine a rack slot designed for a 2‑meter‑tall pallet.

- You place a 0.5‑meter‑tall pallet in that slot.

- Pallet Utilisation: 100 % (the slot is full).

- Cubic Utilisation: 25 % (1.5 m of empty space above the product).

Executive Summary

| Metric | Question it Answers |

|---|---|

| Cubic Utilisation | “Could we redesign our racks to fit more inventory in the same building?” |

| Pallet Utilisation | “Are we running out of empty slots right now?” |

Final Thoughts

Warehouse utilisation isn’t about complex algorithms. It’s about understanding the relationship between:

- The box – the warehouse itself

- The grid – the racking system

- The object – the pallet

Once you separate Cubic Utilisation from Pallet Utilisation, you stop guessing about capacity and start making data‑driven decisions about efficiency.

Feel free to comment, like, and repost.

Don’t forget to connect with me on LinkedIn: LinkedIn