2025-12-21 Daily Robotics News

Source: Dev.to

Robotics Week in Review

Humanoid flair, cutting‑edge manipulation, and bold market moves defined the past week. Below we unpack the technical underpinnings, market ripples, and the path toward scalable robotics.

1. Unitree’s G1 Humanoids Steal the Show

Unitree’s compact G1 humanoid robots performed synchronized dances and acrobatics alongside Chinese‑American singer Wang Leehom at his “Best Place Tour” concert in Chengdu’s Dong’an Lake Sports Park Multifunctional Gymnasium, captivating 18 000 spectators.

Performance highlights

- Back‑flips and fluid choreography to the opening beats of “Open Fire.”

- Seamless interaction with human dancers, earning a “Bigtime” reaction from Elon Musk on X.

Technical specifications

| Parameter | Value |

|---|---|

| Height | ≈ 1 320 mm |

| Mass | ≈ 35 kg |

| Folded size (transport) | ≈ 690 mm |

“Robots in China are doing it all now, even dancing on stage like pros. Here Unitree robots doing back‑flips and are performing at Chinese‑American singer Wang Leehom’s concert in Chengdu.” – Rohan Paul

Why height matters

- Lower centre of mass → improved balance.

- Shorter links → reduced inertia, enabling higher accelerations.

- Smaller actuators suffice for dynamic motions, enhancing safety around humans.

Commercial implications

- Pricing: ~US $16 000 per unit (research platform).

- Cost efficiencies stem from the compact design and mass‑produced components.

- Market outlook: Tuo Liu predicts humanoids performing with singers will soon be commonplace.

“The debut signals broader cultural integration and potential for event‑based deployments.” – Futurism

Critical perspective

Chris Paxton cautioned that dancing is a spectacle compared with practical chores such as dishwashing, where true utility lies. The G1’s exposed structure shows hardware maturity, but the debate continues: does visibility accelerate funding or invite scrutiny?

2. Kyber Labs’ Superhuman Dexterity

Kyber Labs showcased incredibly precise manipulation demos that Chris Paxton called “among the few achieving superhuman levels.”

Demo feats

- Threading needles.

- Assembling intricate parts with sub‑millimeter tolerances.

Key technologies

- Advanced end‑effectors.

- Real‑time perception pipelines.

- Foundation models (e.g., Trace Anything) that predict point trajectories for manipulation and video prediction, reducing the labeling burden in robot learning.

“This is one of the only companies that genuinely seems to have achieved superhuman dexterity.” – Chris Paxton

Broader impact

- Automated micro‑factories – $5 000 box‑sized units that swap tools to build electronics 24/7 (highlighted by Ilir Aliu).

- Tool‑inventing frameworks – VLMgineer enables Vision‑Language Models to design tools and usage actions without templates or demos, outperforming human designs by 64.7 % across 12 RoboToolBench tasks.

These advances point toward general‑purpose hardware iteration without human priors—imagine a robo‑factory that evolves its own tools.

3. Industry Deployments & Research Highlights

| Deployment / Paper | Highlights |

|---|---|

| UPS & Pickle Robot Company | UPS pledged millions to deploy truck‑unloading bots, accelerating logistics automation. |

| Terrain‑Predicting Legged Systems | Recent papers demonstrate legged robots that forecast terrain changes, improving locomotion robustness. |

| MicroFactory Production Boxes | Compact, modular production units that democratize manufacturing (see Ilir Aliu’s tweet). |

| Skepticism from Rodney Brooks | Warns against hype surrounding humanoid robots and urges a focus on functional utility. |

4. Hardware Innovations

- MicroFactory’s mini production boxes – Box‑sized units capable of swapping tools and assembling electronics continuously.

- VLMgineer – Vision‑Language Model framework that autonomously designs tools, achieving state‑of‑the‑art performance on RoboToolBench.

5. Visuals

6. Outlook

- Humanoids are shifting from spectacle to commercial viability as costs decline and designs become more compact.

- Dexterous manipulation is achieving super‑human performance, unlocking new manufacturing paradigms.

- Market traction (e.g., UPS, Pickle Robot) demonstrates confidence in robot‑assisted logistics and micro‑factory concepts.

The convergence of hardware maturity, foundational AI models, and real‑world deployments points to a rapid acceleration toward scalable, practical robotics in the coming years.

Custom Grippers & Zero‑Shot Generalization

Robot Utility Models (RUMs) from NYU and Hello Robot demonstrate zero‑shot generalization, achieving 90 % success in unseen environments for drawer‑opening and bag‑picking without retraining.

- Data collected on iPhone

- Multi‑modal LLM self‑checks

“Paxton’s praise for motion‑prediction lines like NovaFlow and Amplify underscores how video‑derived actions bypass costly labeling, amplifying dexterity gains.”

These advances signal a tipping point: moving from scripted demos to adaptive systems that could slash deployment costs in warehouses or homes with a “train once, deploy anywhere” paradigm.

RSS 2025 Finalist: Forward‑Dynamics Models for Legged Robots

A standout from the RSS 2025 finalists introduces perceptive forward‑dynamics models that predict robot states up to 5 seconds ahead across rough terrain—without manual tuning or rigid limits.

Key Features

- Trained on years of sim‑plus‑real data.

- Fuses perception and proprioception for zero‑shot navigation.

- Boosts success and safety via sim‑to‑real transfer.

“The model’s edge lies in its no‑fuss deployment: minimal cost tuning yields robust locomotion.” – Project site & paper

Implications

- Applications: suitable for quad‑rotors or bipeds in search‑and‑rescue, inspection, and other field missions.

- Humanoid extension: can be integrated with DEEP Robotics’ DR02 (“Motion at Will, Power in Balance”).

- Industrial use: supports Apptronik’s Apollo bots, enabling autonomous factory roaming.

Industry Context

- Tuo Liu’s selfie‑snapping humanoid hints at casual deployments, but reliable rough‑terrain prediction is the real enabler for autonomy.

- This work counters the dexterity‑focused hype by addressing locomotion’s unsolved crux, potentially halving navigation failures in unstructured spaces and accelerating humanoid factory trials.

Logistics Spotlight: UPS & Pickle Truck‑Unloading Robots

UPS is earmarking $120 M for ≈ 400 Pickle truck‑unloading robots, targeting 18‑month paybacks by slashing dock labor and boosting trailer throughput.

Key Details

- Cycle time: One robot unloads a truck in 2 hours using suction grippers for 50 lb cartons that are stacked messily.

- Mobility: Mobile bases drive into trailers and employ perception‑planning loops to make collision‑free picks onto conveyors.

- Strategic fit: Part of UPS’s $9 B automation blitz across 60+ sites, with a goal of $3 B savings by 2028.

“UPS is lining up about $120 M to buy around 400 Pickle truck‑unloading robots, aiming to cut dock labor and speed up trailer turns.” – Rohan Paul

Outlook

- Scaling: Pickle’s recent CFO hire signals a broader rollout slated for late‑2026.

- Industry impact: This narrow‑task win validates mobile manipulators for logistics and aligns with Apptronik’s human‑augmenting ethos.

- Future speculation: As Tuo Liu polls on humanoids replacing café staff in 5‑10 years, Pickle’s success previews a pathway toward humanoid expansions, while specialized bots provide a faster bridge to full‑generality.

Visual Insight

Paxton critiqued ego data’s quick‑gain plateau due to simplistic benchmarks, stressing hand‑pose quality—lessons for Pickle‑like systems iterating on real fleets.

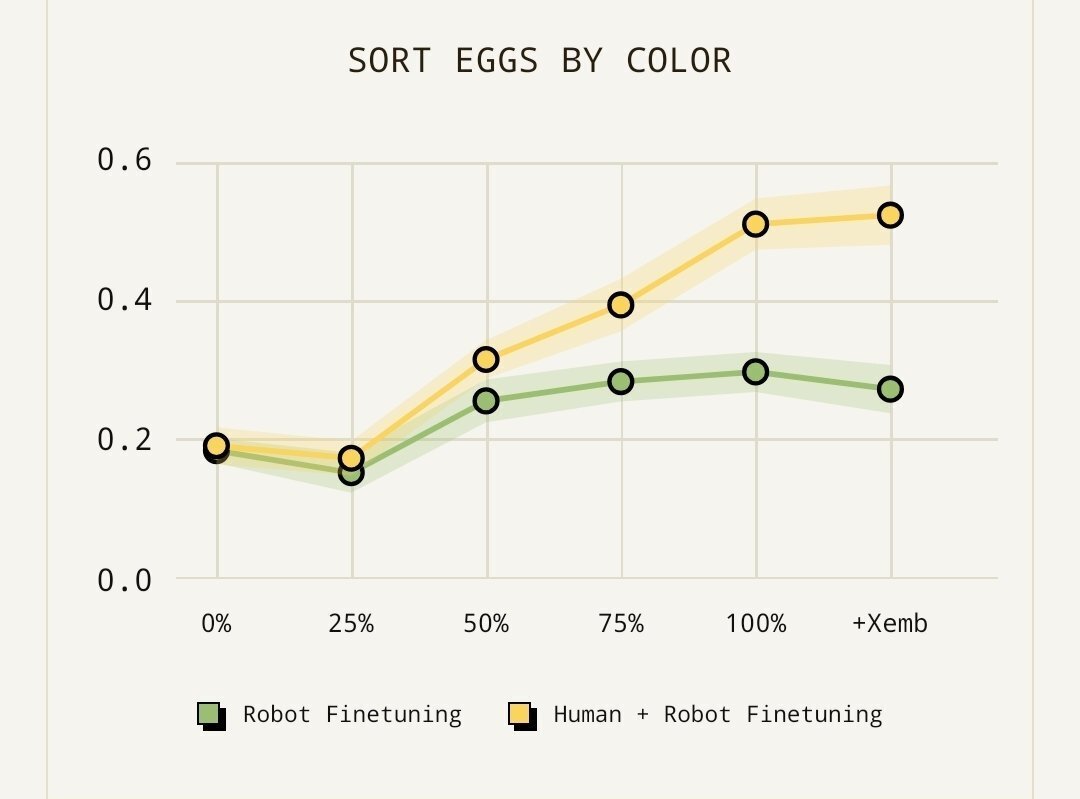

Planning Speedup: 10× Faster World‑Model Planning

A new paper slashes robot planning time by 10× while matching the quality of the Cross‑Entropy Method (CEM).

- Online World Modeling – retrains models on true simulator rollouts.

- Adversarial World Modeling – smooths gradients, closing the train‑test gap.

“A new paper cuts robot planning time by about 10×, yet still reaches the same planning quality as the slower Cross‑Entropy Method baseline.” – Rohan Paul

Technical Depth

- Expert demonstrations train 1‑step predictions, but planning requires multi‑step foresight.

- Adversarial tweaks shrink loss surfaces, guiding optimizers toward accurate “hints” that lead to goals.

The ArXiv pre‑print (2512.09929) demonstrates parity at 10 % of the compute, which is transformative for real‑time humanoids where sampling is a bottleneck.

Implications

- Faster planning unlocks dexterous manipulation chains, synergizing with Kyber precision or RUMs generality.

- Brings us closer to collision‑free homes and factories.

Illustration from Planning Paper

Hardware Trends & Ecosystem

- Robotuo’s Shenzhen HQ – Twitter post showcases the open‑source hub fueling China’s AI‑hardware ecosystem.

- Jeffrey Weichsel’s Vision – He imagines “humanoids like Tesla Optimus with Grok brains ushering unlimited abundance,” enabling artisan‑quality goods at material cost and eradicating poverty through universal entrepreneurship.

“Most people don’t understand how profoundly our world is about to change. Humanoid robots like @Tesla_Optimus, with @grok as their brains, will be able to create anything their owners ask for… There will be no poverty, only wealth.” – Jeffrey Weichsel

-

Elon Musk doubled down, noting that Grok needs no high‑frequency trading for colliders—just Optimus and the Boring Company—to support mega‑projects.

-

Rodney Brooks (creator of Roomba/Baxter) warns against hype, a sentiment echoed by Scott Angelist and Chris Paxton, who discuss addressable concerns such as humanoid readiness.

- Read Paxton’s take: Are humanoid robots ready for the…?

Rodney Brooks Critiquing Robot Hype

Shenzhen’s AI‑Hardware Hub

“Shenzhen probably has the most unique startup ecosystem for AI hardware and robotics, attracting the smartest founders domestically and globally.” – Tuo Liu

- Tuo Liu champions the city’s AI‑hardware hub: Twitter thread.

- Futurism covered the cultural shift with a concert‑style robot showcase: Robots stage backup dancers.

These threads weave a tapestry where dazzling demos meet pragmatic deployments, research fortifies foundations, and debates sharpen focus. Humanoids are inching from stages to shelves, and dexterity is redefining what’s possible.

MicroFactory: “Mini Factory‑in‑a‑Box”

- Concept – A $5,000, 24/7‑operating unit with swappable tools that can build electronics autonomously.

- Tweet – Ilir Aliu’s announcement.

- Capabilities – Handles PCB assembly or 3D printing via modular bays, ideal for rapid prototyping during supply‑chain crunches.

“A mini factory in a box – Runs 24/7 – Costs $5,000 – Tools can be swapped – Builds electronics by itself.” – Ilir Aliu

Significance

- Costs drop from industrial‑scale millions to consumer‑scale thousands.

- Enables on‑demand, resilient supply chains.

- Can pair with RUMs for household manufacturing or scale to UPS‑style logistics for just‑in‑time parts.

Shenzhen Ecosystem Visual

RUMs (Robust Universal Manipulators)

- Performance – 90 % zero‑shot success across 25+ environments.

- Open‑source project page – GitHub/RUMs